In a previous article we discussed 4 reasons to consider remote vibration monitoring. In this article we will further discuss the various options for implementing such systems. We discuss various configurations and the required hardware and software.

System structure

Every configuration consists of the following phases:

- Data-acquisition with vibration sensors

- Data processing using a vibration monitoring system

- Data transmission

- Data storage

- Data visualisation for vibration analysis

Hardware

1. Vibration sensors

Accelerometers are generally used to measure machine vibrations on ball bearing machines. Proximity / eddy current sensors are generally used with sleeve bearing machines. However, in some cases velocity sensors are used as these could provide better measurement results for specific applications. The sensors are connected to the measuring system with a cable and send a continuous signal to this system for further processing. Which sensors are most suitable for your application depends on several factors, such as maximum vibration amplitude, sensitivity and environmental factors. The article below provides more information about the sensor offering and the correct sensor choice.

Read more about different sensor types »

2. Vibration monitoring system

A vibration monitoring system is required to process vibration data. From this system, the data can be further distributed, e.g. to a local computer or server for data analysis and visualisation. Different types of measurement systems are available, which differ in the number of channels. If you have not yet installed a vibration measurement system, the article below provides insight into the available options.

Read more about vibration monitoring systems »

3. Data transmission

From the vibration monitoring system, the vibration data is sent to a central point to enable remote vibration monitoring. This can be a local computer / laptop or server, or directly to a remote server / cloud using a 4G modem.

4. Data storage

One of the advantages of a remote monitoring system is that the data does not have to be stored locally. It can be sent directly from the system to the vibration specialist using a 4G modem. In that case, the raw data is stored on an external Istec server / cloud. In other configurations, the data is stored locally and the vibration specialist can retrieve the vibration data remotely (read “Configurations”)

Software

Depending on the configuration, advanced vibration monitoring and analysis software is required. With this software, extensive vibration analyses can be performed and the vibration data can be visualised. If the computer / laptop which has the software installed is connected to a 4G modem or an existing network, vibration specialists can perform vibration analyses remotely using this software.

Configurations

The hardware and software that is required to install a remote vibration monitoring system depends on the preferred configuration. Three different configurations are distinguished. Note that the configuration examples below use Istec’s hardware and software choices.

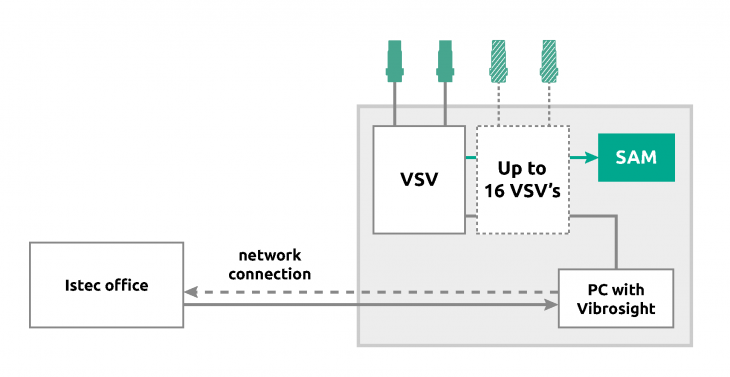

1. Local data storage with a local network for communication

In this configuration, the raw vibration data is stored on a local PC or server. The customer requires his own license for the advanced vibration monitoring and analysis software; VibroSight. With this configuration, there is no continuous data transfer to Istec, but the connection is only made when an alarm is triggered.

Alarm

When the vibrations exceed the pre-set alarm values, the vibration specialist is notified. The specialist has access to the local PC or server via the existing network, enabling remote vibration analysis.

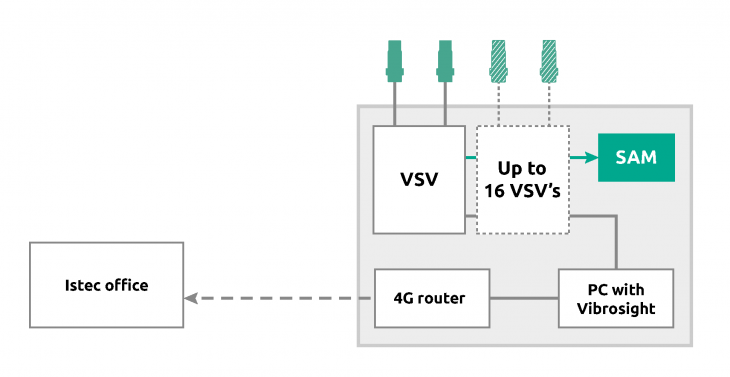

2. Local data storage with a 4G modem for communication

In this configuration, the raw vibration data is stored on a local PC or server. The customer requires his own license for the advanced vibration monitoring and analysis software; VibroSight. There is no continuous data transfer to Istec, but the connection is only made when an alarm is triggered.

Alarm

When the vibrations exceed the set alarm values, the vibration specialist is notified. The specialist has access to the local PC or server via a 4G modem, which enables remote vibration analyses.

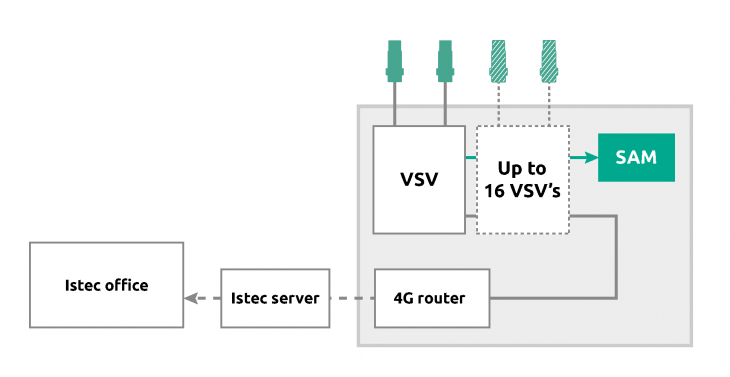

3. External data storage with a 4G modem for continuous data transmission

In this configuration, the raw vibration data is continuously sent to the Istec server via a 4G modem. The customer does not need a VibroSight license for this. As the data is stored on an external server, local storage is no requirement for this configuration.

Alarm

When the vibrations exceed the set alarm values, the vibration specialist is notified. The vibration specialist has direct access to the Istec server and can perform remote vibration analyses and send them to the customer, including complete reporting and maintenance advice.