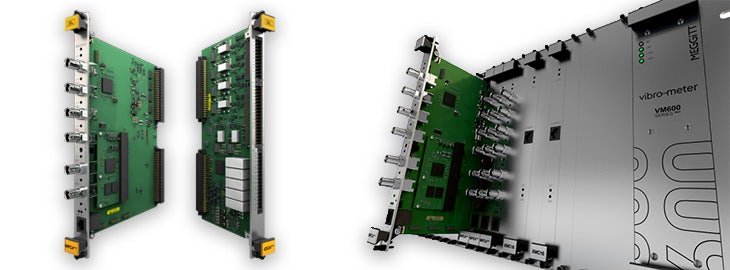

In this article, we will explore the reasons behind the launch of the VM600Mk2, the second-generation vibration protection and monitoring system by Meggitt Vibro-Meter. The original VM600 has long been the flagship solution for protecting and monitoring critical rotating machinery.

Despite the VM600’s extensive feature set and proven innovation, the development of a second-generation system was essential to meet evolving customer demands. In this article, we discuss the multiple factors driving this innovation.

Go to the VM600Mk2 product page »

Cybersecurity: A New Industrial Imperative

When the original VM600 was designed, the internet was still in its infancy, and cybersecurity threats to industrial systems were virtually nonexistent. Today, cybersecurity is a top priority, particularly for sectors like power generation where vulnerabilities in infrastructure can have far-reaching consequences.

Modern cyberattacks no longer target only traditional IT systems; they extend to industrial control platforms such as SCADA systems and PLCs. High-profile incidents like the Aurora Generator Test and Stuxnet have highlighted the real-world risks.

To address these threats, the VM600Mk2 Second Gen Vibration Protection introduces advanced cybersecurity features, mitigating risks while maintaining separation between protection and condition monitoring functions.

Unified Integration for Enhanced Monitoring

Integration challenges were a significant limitation in the legacy VM600 architecture, where protection and condition monitoring systems operated separately. While beneficial for cybersecurity, this separation complicated the real-time analysis of protection system alarms.

The VM600Mk2 overcomes these barriers by offering:

-

A unified environment for viewing both protection and condition monitoring statuses

-

Synchronized data across different modules

-

Reusable configuration settings

This next-generation system ensures full API 670 compliance while streamlining operations.

Future-Proof Hardware and Component Availability

Industrial protection systems are expected to operate reliably for 15–20 years. Ensuring long-term component availability is critical for maintaining hazardous area certifications and SIL approvals.

Replacing outdated electronic components isn’t always feasible due to the lack of suitable replacements and the potential need for recertification. Even securing last-time buys of components has limitations.

The VM600Mk2 addresses this by using modern hardware designed for longevity, ensuring a sustainable and certified platform for the future.

Backward Compatibility: No “Rip and Replace” Needed

Introducing a new platform presents the challenge of avoiding “rip and replace” requirements. Customers are not happy when they’re told that they must remove the old hardware completely and replace it with new hardware. This is even more the case when the new system is substantially different from its predecessor, making it impossible to reuse wiring connections, panel cutout and mounting dimensions must be modified, different software must be used, or even the power and ventilation requirements must be changed.

From a manufacturer’s standpoint, “rip and replace” is also undesirable because it makes it as easy and cost-effective for customers to switch to a different supplier as it is to stay with the existing supplier. Backward compatibility with the previous platform is therefore in everyone’s best interest, while also introducing necessary improvements to address the continuously evolving list of customer needs.

Meggitt Vibro-Meter ensured that existing customers would not have to face inconvenient “rip and replace” methods when installing the second-generation VM600.

In Summary

The launch of the VM600Mk2 addresses several critical factors:

-

Rising cybersecurity concerns

-

The need for integrated protection and monitoring

-

Long-term component availability

-

Minimizing upgrade disruptions

With the VM600Mk2 Second Gen Vibration Protection, Meggitt Vibro-Meter delivers an advanced solution that meets current industry challenges while rewarding existing customers with a smooth transition path.

Learn more about the key differences between the first- and second-generation VM600 »