Since the operational importance of this type of installations is very high, as much relevant data as possible will be collected and analyzed. The most effective way to monitor these machines is through an online data analysis system, where alarms are generated. This makes it possible to respond immediately when the installation reaches a critical vibration level.

An essential component is the presence of an online system with sufficient capacity. For the most effective monitoring, OPC data is just as crucial as vibration data. With this data, the analysis can extend beyond just vibration data. Especially with larger installations (such as steam turbine-generator sets with multiple steam turbines), changes in vibration data in one area can originate from another part of the machine. To adequately identify this source, vibration data alone may not be enough. OPC data, such as bearing temperatures, relative expansions, shaft positions, and steam temperature, may be required to form a complete assessment of the machine.

For an online system, it is desirable to use a system where additional alarms can be programmed beyond those provided by the monitoring system. This allows for the programming of a “smart” system. These alerts are made available to the data analyst. After reviewing the alert, it is desirable to log into an online data analysis system to conduct further analysis. If this analysis reveals that the machine’s reliability is at risk, a notification will be generated and sent to the client, allowing them to take appropriate action.

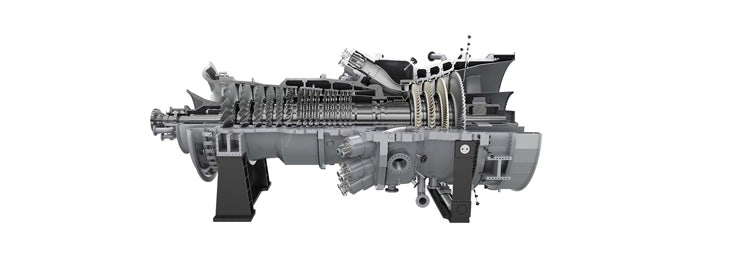

Photo: Siemens SGT6-5000F