This article is part of the whitepaper: “monitoring mechanical behaviour of reciprocating machinery”. Request the whitepaper here »

Temperature monitoring is essential for various components of reciprocating compressors. This article discusses valve temperature and bearing temperature monitoring; the most critical temperature applications for reciprocating compressors.

Valve temperature

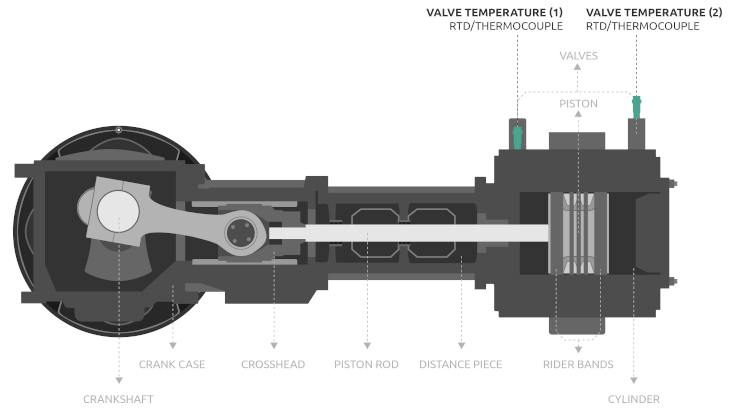

The suction and discharge valves are typically the most maintenance-demanding parts of reciprocating compressors. Faulty valves are considered the main cause for unplanned shutdowns of reciprocating compressors. The monitoring of valve temperature offers insight into the condition of the valves. If a leak occurs at one of the valves the valve temperature changes. By monitoring valve temperature, a defect at the valves can be detected quickly. Monitoring valve temperatures is essential, as defective valves can significantly decrease the efficiency of reciprocating compressors.

RTD or thermocouple sensors are used to measure valve temperatures. There are two common ways of positioning these sensors:

- Sensor positioning in the valve through a thermowell (1).

When the temperature sensor is mounted in a sleeve that is installed in the valve pocket, the quality of the measurement is higher than measurements on the valve cover. There are no environmental conditions that influence the measurement using this type of sensor positioning. The sensors that are installed in the valve pocket also provide a faster detection of changing temperatures and valve leaks. However, the valve design is not always suitable for the installation of thermowells (figure 1). - Sensor positioning on the valve cover (2).

Mounting the temperature sensor directly to the valve cover makes the sensor vulnerable to be influenced by environmental conditions. It also has a slight delay on detecting valve leaks compared to the aforementioned method (figure 1).

Bearing temperature

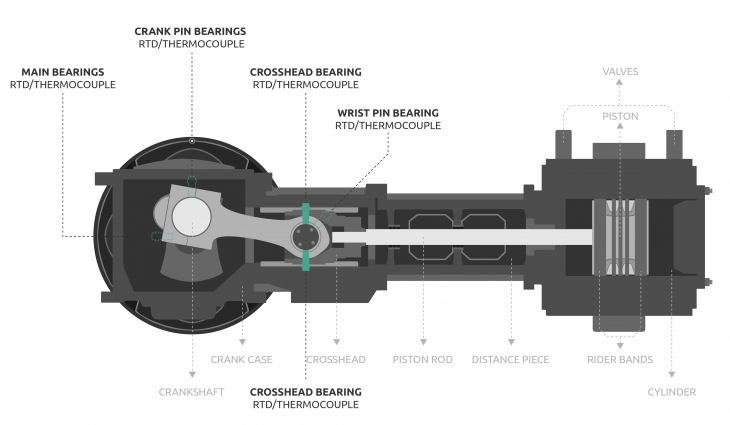

The bearings of reciprocating compressors assure the proper running of the compressor. It is important to monitor the temperatures on the bearings as overheating could lead to bearing failure, which may in turn lead to damage or downtime. Various types of bearings are fitted on different locations of the reciprocating compressor.

- Main bearings are located in the frame to position the crankshaft properly.

- Crank pin bearings are located between the crankshaft and the connecting rod.

- Wrist pin bearings are located between the connecting rod and crosshead pin.

- Crosshead bearings are located at the top and bottom of the crosshead.

Pressurized oil is supplied to the bearings through grooves on the bearing surface in order to prevent overheating. If the oil supply is failing or friction increases the bearing temperatures will increase to a point where damage is likely to occur.

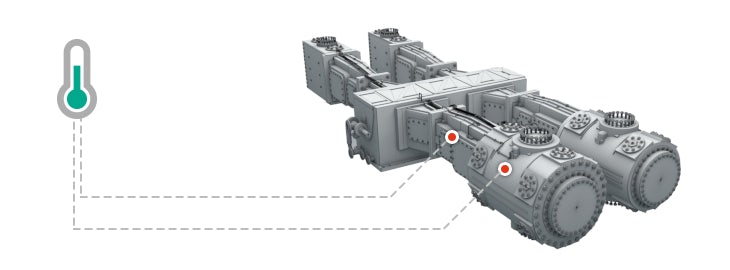

RTD or thermocouple sensors are used to monitor the temperature of main bearings, crank/wrist pin bearings and crosshead bearings (figure 2). They are externally mounted and include a conduit head to be able to access the sensor and cabling.