This article is part of the whitepaper: “monitoring mechanical behaviour of reciprocating machinery”. Request the whitepaper here »

Rod drop is an important mechanical indicator for gaining insight into rider band wear. This article discusses what is needed to ensure reliable and accurate monitoring of this critical parameter for reciprocating compressors.

Rider bands are critical components that support the piston while its moving through the cylinder. They are used to correctly position the piston in the cylinder, to prevent metal-to-metal contact between the cylinder wall and the piston. These rider bands wear out over time, which results in a vertical displacement of the piston and the piston rod. To prevent damage to the piston and the cylinder wall, the condition of the rider bands should be monitored.

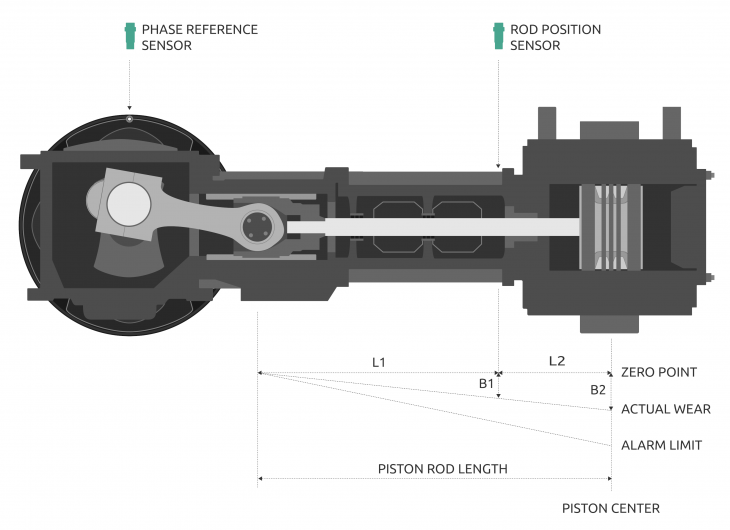

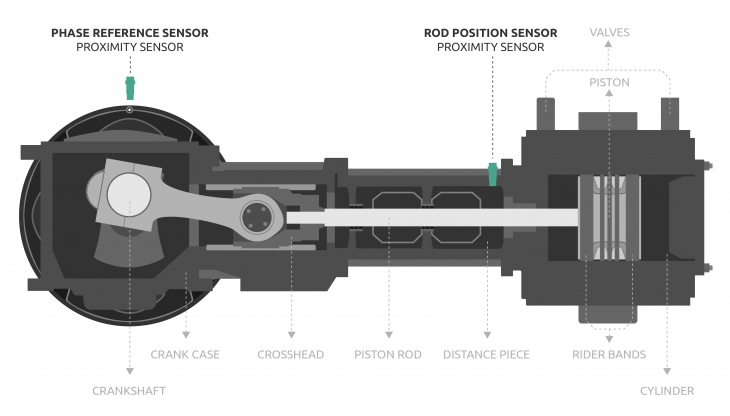

Proximity sensors are used to monitor rider band wear. However, it is difficult to directly monitor the vertical displacement of the piston due to high pressure inside the cylinder. Instead, the vertical displacement of the piston rod is monitored, which is proportional to the drop of the piston. Monitoring vertical rod displacement is therefore a reliable method to monitor rider band wear (figure 1).

The proximity sensor must be mounted vertically (90 degree angle) under or above the piston rod, as close to the cylinder as possible (figure 2). Optionally, a second proximity sensor can be mounted in the same way, but positioned horizontal to the piston rod (X-Y monitoring). By installing a second sensor (horizontal) it is possible to measure horizontal displacement of the piston rod, which is necessary to be able to do rod flex measurements.

Phase reference sensors are used to filter the displacement signal to the right phase angle. The sensor enables measurements of the piston rod displacement at a specific point during the cycle. The sensor is crucial for reliable monitoring of rider band wear because the vertical displacement of the piston rod must be measured at a specific point during the rotation of the shaft (figure 2).

Istec RecipSys 200

The RecipSys 200 is a compact monitoring system for reciprocating compressors. It delivers accurate real-time data of rider band wear, eliminating the need for periodic production shutdowns for manual inspections. The transmitter-based system is affordable and extends the range of compressors which can be monitored.