Vibration analysis services for wind turbines

Istec offers vibration analysis services for wind farms, providing insights into asset health. With Europe’s largest in-house team of highly certified vibration analysis experts, we support wind farm operators and owners in their mission to operate their wind farms at optimal performance levels.

Why operators choose Istec

Brand-independent for full objectivity

Our brand-independent services provide the flexibility to work with vibration data from any system, ensuring objectivity in our analyses. This approach not only guarantees unbiased results but makes us the ideal partner for reliable second opinions.

A shared objective: maximizing wind turbine lifespan

Our services support asset managers, reliability managers, maintenance managers, and similar roles in enhancing their capability to meet and exceed their objective to maximize the lifespan of wind turbines.

Europe’s largest in-house team of vibration experts with GWO certification

Our team of vibration experts is GWO certified and operates across Europe, primarily focusing on the Netherlands, Belgium, Germany, and the UK, while offering vibration analysis services to a wide range of clients throughout the entire continent.

Vibration analysis services

Periodic vibration monitoring

Monitoring the condition of wind turbines is crucial for ensuring their longevity and operational availability. Vibration monitoring is one of the most accurate methods for detecting developing damage at an early stage. Istec offers services to periodically perform vibration analysis, providing accurate insights into your asset’s health.

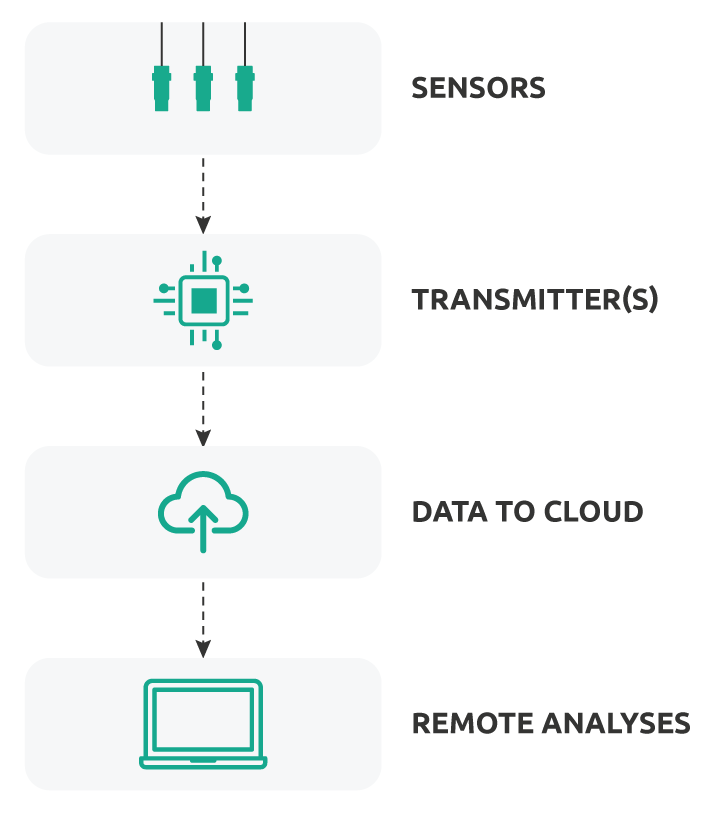

We prioritize data acquisition systems that enable remote vibration analysis, optimizing cost-effectiveness in machine insights. However, when onsite data acquisition is necessary, our team is fully equipped and ready to visit and directly assess the wind turbines.

Troubleshooting

Many wind turbines in Europe are reaching the end of their lifecycle, and as new wind turbines become larger and heavier, these developments can lead to unexpected operational issues. Our goal, through our vibration troubleshooting services, is to identify the root cause.

End of Warranty analysis

Our End of Warranty analysis service is designed for wind turbine owners to deliver a brand-independent assessment. As warranties approach expiration and maintenance responsibility shifts to the owner, our analysis provides an objective evaluation of turbine health.

Case study: Vibration monitoring and analysis on wind turbines in the Netherlands

Windunie is a collaboration between owners of wind turbines throughout the Netherlands. The warranty of some of the wind turbines at one of their wind parks was expiring at the end of 2022. Windunie has engaged Istec as brand-independent vibration specialist to monitor the condition of the turbines.

When the warranty of a wind turbine is about to expire, a final inspection is conducted by the manufacturer (OEM) of the turbine to assess their mechanical condition. During this inspection multiple parameters are measured and analyzed to determine the condition of the wind turbines.

To ensure additional insight into the mechanical condition of the wind turbine drive train and the effectiveness of the condition monitoring program, Windunie has contacted Istec, as independent third party, to conduct vibration analyses on two Vestas wind turbines.

Hardware

In addition to our customer-focused services, we offer a comprehensive range of hardware solutions hardware solutions covering key parameters like vibration and speed in wind turbines. With our technology, we optimize performance and enable early issue detection, minimizing downtime and maximizing output.

Vibration monitoring hardware

High quality vibration data starts with reliable and advanced hardware. Istec offers vibration sensors with a wide frequency range, suitable for wind turbine applications. We also offer a variety of vibration monitoring and protection systems from various renowned brands.

Speed monitoring hardware

Our SpeedSys® tachometer product line is dedicated to monitoring speed. The single, dual, and triple-channel devices enable overspeed, underspeed, acceleration, reverse rotation, standstill, and dynamic sensor monitoring on wind turbines.

Committed to the wind industry

Certifications

ISO 18436-2 – Condition monitoring and diagnostics of machines

The Istec team is the largest brand-independent team of vibration specialists in Europe. The team comprises a mix of CATI, CATII, CATIII, and CATIV vibration specialists.

Global Wind Organisation (GWO) certified vibration specialists

GWO courses are intended for individuals working in the wind industry. The vibration team at Istec consists of wind turbine vibration specialists who are GWO certified.

NedZero

Istec is a proud member of NedZero, the Dutch Wind Energy Association. Through our membership, we share our knowledge and expertise with the Dutch wind industry, contributing to the growth and development of this sector.

Ask our expert

Prudent person standard for wind turbines through periodic vibration monitoring

The prudent person standard is a legal principle that assumes a person behaves reasonably as a responsible person and does everything necessary to prevent (foreseeable) damage. It is therefore important…

What costs can be avoided with vibration monitoring in wind turbines

Wind turbines are exposed to high wind speeds, temperature variations, and mechanical forces. Over time, these factors can cause wear and tear, potentially leading to costly malfunctions and a reduced…

The importance of brand-independent vibration analysis for wind turbines

The importance of vibration measurements can overlap for OEMs (Original Equipment Manufacturers) and wind turbine owners, but there are also some differences in their perspectives and priorities. Factors such as…