In many industrial processes control screenings and fractionation play an important role, as well as the reliability of the used screens. In continuous processes a screen damage can cause significant costs. In case of such a damage great quantities of screening material have to be destroyed or sieved again. A product recall, if necessary, can be very expensive for the manufacturer. The analysis of grain size in a material flow is time consuming and not suitable for the detection of a sieve failure arising in a short term. Even a continuous maintenance or a regular exchange of the sieves can‘t prevent a defect. The screen break detection Paddy is helpful here.

Solution

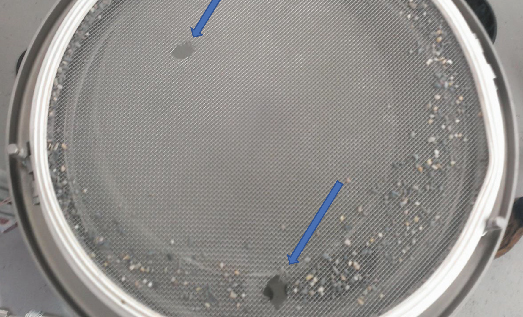

Paddy is a particle sensor which is able to detect a grain size range online. It consists of two sensors, a measuring sensor and a reference sensor. For a successful measurement a minimal freefall of 500 mm is required. Thereby the product stream, which has to be homogenized by two added baffles, can be monitored promptly and constantly. Paddy uses state-of-the-art microwave technology in combination with intelligent evaluation software. The method can be used for solids in metal pipes, conveyed in freefall or pneumatically.

- View product page of Paddy (Dutch)