In the past, overspeed turbine protection systems were often designed by the turbine OEMs themselves as part of the mechanical system. These mechanical protection systems are still in use, especially on medium-sized machines. However, electronic systems offer significant benefits and are becoming increasingly accessible, in both their economical and technical impact. This article explains the benefits of electronic protection over mechanical protection.

The principle of mechanical overspeed protection

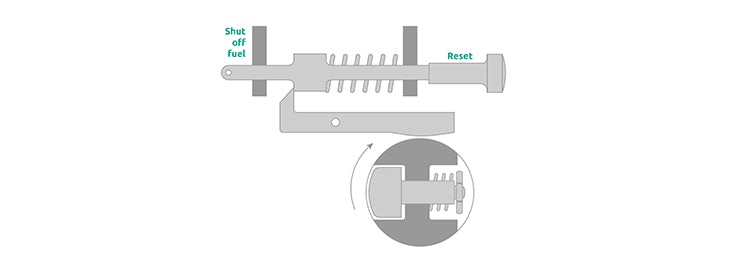

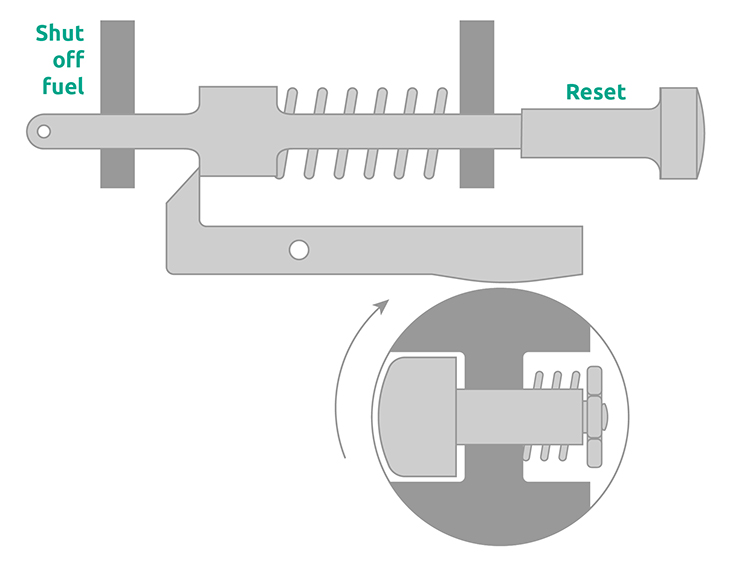

To understand the difference between the two types of protection, it is important to understand how mechanical overspeed protection works. Mechanical overspeed protection systems use a weight on a spring of which the spring force is known. Due to the centrifugal force as a result of the shaft rotation speed, the spring is stretched further and further and the weight moves out. As long as the rotational speed is still within the design specifications, the spring will not stretch too far and the weight will not protrude. However, if it exceeds its design specifications, the weight will run out and hit the trip bolt. This will release the pin and the trip will be activated.

The operation of a mechanical overspeed monitoring system.

The principle of electronic overspeed protection

Electronic overspeed protection consists of a gear or other measuring surface, speed sensors and a measuring system with trip logic and relay outputs. The speed sensors look at the measuring surface and give a sine or square wave signal, which the measuring system sees as pulses. The measuring system then counts the time between pulses to determine the rotation speed. The relay outputs are controlled by trip logic. In order to increase safety and availability, these protection systems are often built with redundant voting structures.

Why switch to electronic overspeed protection?

Switching from mechanical overspeed protection to electronic overspeed protection has significant advantages. Verifiable security is the primary argument. To illustrate: where mechanical overspeed protection systems have to be tested by actually overspeeding the machine (with all the risks involved!), an electronic overspeed protection system can be tested by simulating overspeed. In addition, a simulated test is quicker and easier to perform.

In this overview we compare both forms of machine overspeed protection:

| Mechanical overspeed trip | Electronic overspeed trip |

|---|---|

| Inaccurate trip value determination due to inaccurate spring force (+ / a-50 rpm) | Very accurate trip value determination |

| Trip value shifts slowly due to material fatigue of the spring | Trip value will not change |

| No possibility of user interface | Provides possibilities for DCS interface |

| Must be attached to shaft or mechanical lever | No physical contact with shaft or mechanical lever required |

| Lubricant build-up can block the operation of the mechanical trip | Lubricant build-up has no effect on trip function |

| Cannot be tested, except when disconnected from the driven equipment, which requires shutdown | Safe possibility to test trip function by means of overspeed simulation using a frequency generator |

| Overspeed required to activate trip | Can be tested at any speed and any channel can be tested during operation (online) |

| Requires multiple turbine startups to set trip value as accurately as possible | Does not require additional turbine start-ups |

Switching to electronic overspeed protection is not complex. Firstly, the mechanical trip lever and all associated system components are removed. Secondly, a measuring surface (gear) is mounted on the shaft if this is not already available, after which one or more sensors are placed around this measuring surface. The monitoring system can then be placed near the machine or in a cabinet.

Learn more about overspeed:

What does the API Standard 670 state about overspeed detection systems? »

SpeedSys 300 – Overspeed Protection System

The SpeedSys 300 is a SIL 3 rated electronic overspeed protection system for rotating machinery. It delivers the core layer of protection with a compact architecture. Its small technical footprint enables low-impact retrofitting and extends the range of machinery which can be protected.

Learn more about SpeedSys 300 »

The speed product brochure provides a complete overview of our tachometers, overspeed detection systems, and speed sensors.