A completely oil-tight bearing temperature sensor range to prevent oil-leakage

Temperature sensors are used in many industrial applications and often endure harsh process conditions. Bearing temperature sensors are used to measure the temperature of bearings, which is a key indicator for oil film and bearing health monitoring. These bearings are lubricated with oil, which means that the sensor is exposed to oil.

A common problem in industrial machinery is oil leaking through the sensor installation because it is not completely oil-tight. To tackle this problem Istec and its partner H&B sensors have developed a range of fully oil-tight bearing temperature sensors (RTD and thermocouple), supported by an oil-seal.

The problem

Oil-leakage due to sensors not being fully oil-tight is a common problem in industrial machinery. Temperature sensors are used in many industrial installations and require part of the sensor to be inside the machine and the other part outside the machine. To be able to install these temperature sensors a hole in the housing of the machine is required. Due to the pressure of the oil inside the machine and the capillary function of the cable(s), many companies have problems with completely sealing the sensor installations and regularly have to deal with oil leaks (see figure 1).

Figure 1. Example of an oil leak inside a sensor installation as a result of insufficient oil barriers.

The solution

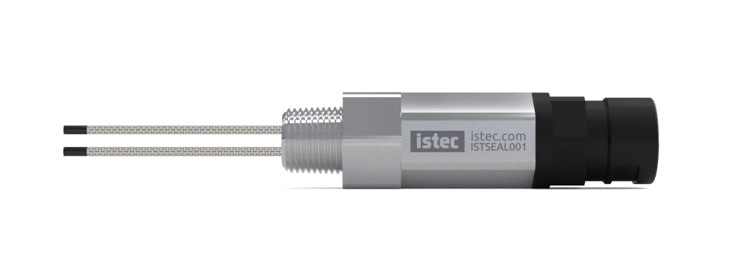

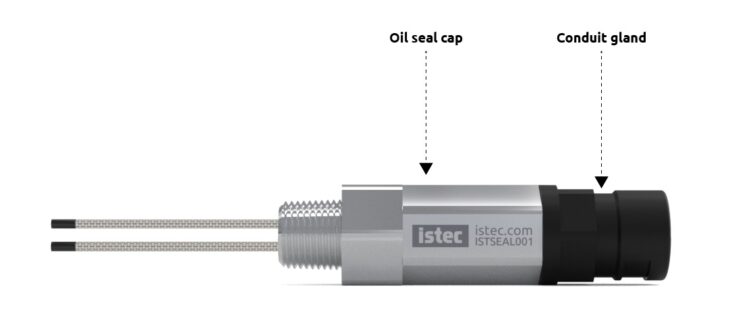

Together with our partners from H&B we developed a comprehensive solution to solve this problem once and for all, which consists of a miniature bearing temperature sensor and a matching multi-sensor sealing gland. The sensors come in two versions: an oil-tight thermocouple (TCS580) and RTD sensor (RTD580), and are available in simplex and duplex variants. The small-sized sensor tip allows for quick measurements and easy installation. Combining these sensors with the Istec multi-sensor sealing gland ensures a fully oil-tight temperature measurement solution for bearing applications (see figure 2 & 3).

Figure 2. An outside view of the complete Istec oil-tight temperature sensor assembly.

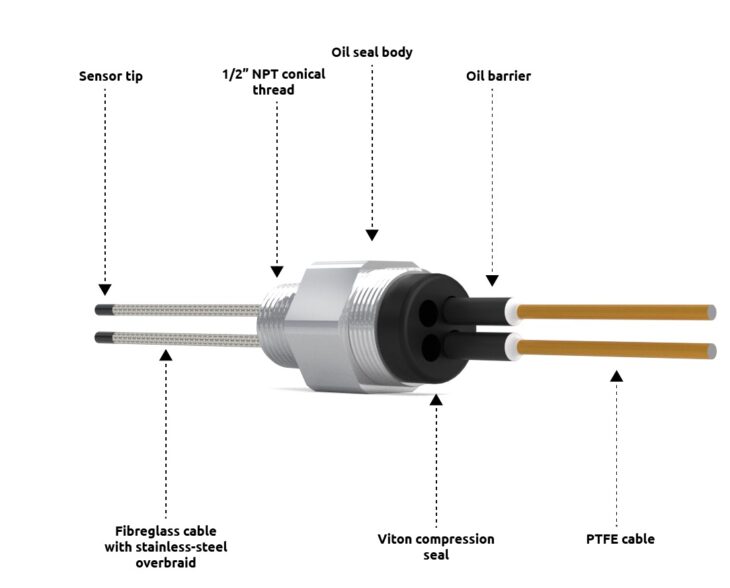

Figure 3. An overview of the components inside the Istec oil-tight bearing temperature sensor.

By extensively testing and optimizing the sensor and barrier assembly, Istec created a durable oil-tight solution for applications up to 5 bar. Each sensor is leak-proof pressure tested (2 bar, 20 °C) before release.

The sensors have multiple layers to ensure a fully oil-tight solution.

1. Cables

The insulated cables inside the machine are made of fibreglass to avoid capillary flow inside the cable and are braided with stainless steel (SSOB) to protect the cable from mechanical damage. The cables outside the machine are made of PTFE material.

Figure 4. The cables inside the machine are made of fibreglass and are braided with stainless steel, while the cables outside the machine are made of PTFE.

Figure 4. The cables inside the machine are made of fibreglass and are braided with stainless steel, while the cables outside the machine are made of PTFE.

2. Oil barriers

The oil barrier is designed to match the sealing in our cable gland. Istec used 6mm oil barriers to make the temperature sensors completely oil tight.

Figure 5. The oil barriers are used to make sure no oil leakage is possible via the cables. The small barriers have a diameter of 6mm and a length of 50mm.

3. Multi-sensor sealing gland

The sealing gland / compression seal has four sensor feedthroughs to allow for a high number of temperature sensors. It is designed to fit perfectly with the oil barriers on the sensor. The compression seal is made of FKM (Viton®) for high chemical resistance and use in high temperature environments.

Figure 6. The FKM compression seal with four sensor feedthroughs.

Are you interested in learning more about our oil-tight temperature sensors?

Learn more about our oil-tight thermocouple bearing sensor »

Learn more about our oil-tight RTD bearing sensor »