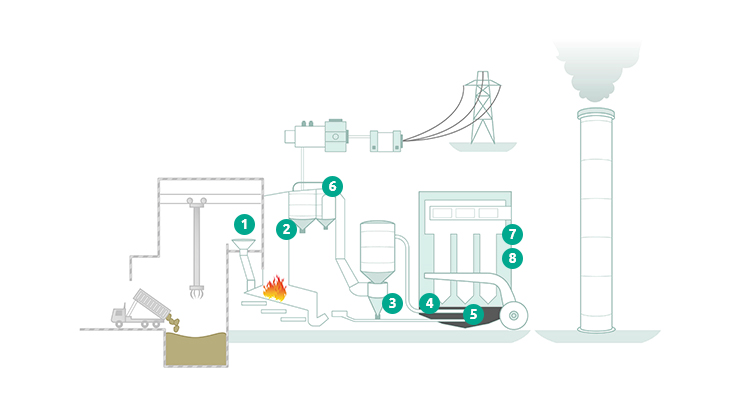

In a waste-to-energy plant, various subprocesses convert waste into energy. The entire process can be roughly divided into four subprocesses: waste intake, resource recovery, the combustion process, and flue gas cleaning. In this article, we highlight which flow and dust measurement equipment we offer for each subprocess to monitor and control this continuous process.

Flow and dust measurement equipment:

- ProGap for level measurement in hoppers

- SolidFlow 2.0 for mass flow measurement of absorbent

- FlowJam for flow/no-flow detection at cyclone exit

- ProGap for ash level measurement at filter discharge

- FlowJam for flow detection in the ash transport system

- ProGap for level measurement in storage silos

- Dusty C for performance trend signals for predictive maintenance

- AirSafe for environmental air monitoring inside filters

Istec is also specialized in:

- Temperature instrumentation – resistance thermometers and thermocouples

- Machine condition monitoring

Continuous process requires reliable monitoring

Proper monitoring of a waste treatment process is important for two main reasons. Firstly, a waste treatment plant has obligations to the government, such as the amount of waste it must process per year or the amount of heat (district heating) or energy it must provide. It is essential for the process to run continuously because, if for any reason waste cannot enter the furnace, the process will cool down, and it will take a long time to bring the combustion process back to full operation. Secondly, monitoring is crucial due to increasingly strict emission regulations.

Waste intake into the waste bunker

For optimal combustion, the waste needs to be of consistent quality. The waste is mixed in the waste bunker, and large claws then deposit the waste mixture into the hoppers of the incinerators. To monitor how full the hoppers are, the ProGap can be used (1).

Resource recovery

Some waste is non-combustible and remains at the bottom of the boiler as bottom ash, which is cleaned and reused. Large amounts of iron and non-ferrous metals, such as aluminum and copper, are recovered. ProGap can be used for level monitoring in storage silos (3)(6).

Combustion process

After the combustion process, an absorbent is added to the flue gas to capture certain particles. It’s crucial to monitor the amount of absorbent added, as both too much and too little can be problematic. This can be monitored using SolidFlow 2.0 or PicoFlow (2).

Flue gas cleaning

The final subprocess is cleaning the flue gas, so only water vapor is released from the chimney. The flue gases are purified in several steps, and useful products are recovered during each stage.

In the first stages, airborne particles are captured by an electrostatic filter at the boiler outlet. This fly ash can be used as filler for asphalt and is transported by trucks. MaxxFlow can be used here to prevent overloading during truck filling.

The next step is flue gas purification using a fabric filter (also called a bag or sleeve filter). These filters can become clogged or torn. If the main concern is detecting tears, installing a Dusty C at the end of the fabric filter is sufficient. If a filter tears, excessive dust will be detected in the cleaned flue gas, triggering an alarm. The Dusty can also provide a trend signal as the output is a 4-20 mA signal (7). ProGap can monitor the ash level (4).

AirSafe can be used to monitor the air quality in enclosed spaces, providing an effective solution for monitoring and controlling dust concentrations. AirSafe prevents the creation of explosive dust zones, monitors dust concentrations in work environments, and quickly detects the escape of dust from system components.

Vibration measurements and services for rotating machines

The waste treatment process involves many rotating machines, such as pumps to circulate (cooling) water, fans to move flue gas, and turbines for power generation. Istec provides products and services for vibration monitoring of rotating machines to support machine condition monitoring and protection. In addition to supplying sensors and measurement equipment, Istec specialists conduct vibration measurements on rotating machines and install monitoring systems for vibration and overspeed protection.