In part 2 of this series, the financial arguments and implications of a maintenance policy without a condition monitoring system were discussed. This follow-up article will focus on the financial arguments and implications of a maintenance policy with a condition monitoring system in place. As covered in the previous article, many factors play a role in the overall financial picture here as well.

Costs of the system and installation

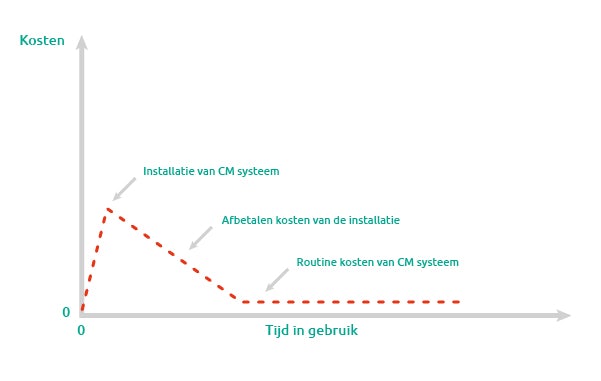

Clearly, the condition monitoring system involves significant costs. These include purchase costs, installation costs, and operational costs. Additionally, considerations must be made for accessibility, installation of foundations, protection, power supply, and service access. Consultancy costs may also arise during the installation process. Ideally, the condition monitoring system is implemented during a scheduled downtime to avoid production losses. Furthermore, employees may require training to operate the system, which incurs additional costs (see Figure 4).

Figure 4. Typical cost model for condition monitoring system installation

Operational costs

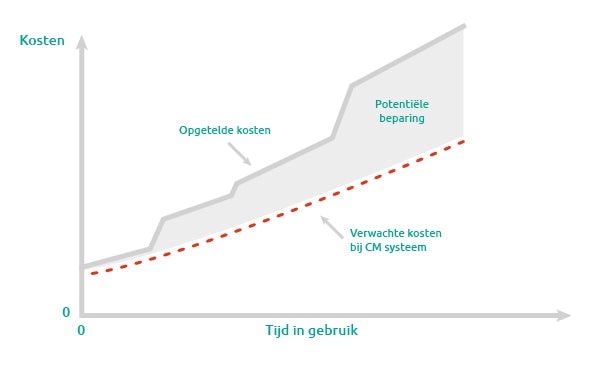

After purchasing and implementing the condition monitoring system, the primary ongoing costs are for personnel. However, assuming the staff receives (the right) training, cost savings are possible. The system saves a considerable amount of time, and time is money. Without a system, engineers would be required to conduct measurements in various locations on the machine. The condition monitoring system can gather this data at one central point, where it can be interpreted with analysis software (such as VibroSight). This setup enables quicker and more accurate conclusions. Additionally, predicting wear without a system is difficult. Large-scale maintenance activities can instead be replaced by smaller, more targeted actions.

Personnel costs vary greatly per factory. However, it is relatively easy to estimate potential savings. Personnel costs for installation, training, operation, and necessary maintenance can be compared to those associated with the current maintenance strategy, for which clear data should be available.

In addition to personnel and training costs, operational costs also include those necessary to keep the system running, such as constant power supply. Although these costs are relatively low, they must still be included in the financial assessment.

Figure 5. Potential savings with a condition monitoring system

Continue with part 4 of this series:

Financial calculations for the purchase of a condition monitoring system