Enhancing operational safety at OCI Nitrogen’s nitric acid plant with the Istec SpeedSys 300

At OCI Nitrogen’s nitric acid plant, a critical machine train has been significantly upgraded with an advanced overspeed detection system. This enhancement aligns the operational safety with the latest API670 standards for machine protection, ensuring improved safety and availability. To achieve this, OCI Nitrogen opted for the Istec SpeedSys 300, showcasing their commitment to safety.

Challenge

OCI Nitrogen wanted to upgrade their system by installing a dedicated overspeed detection system on a critical machine train.

Solution

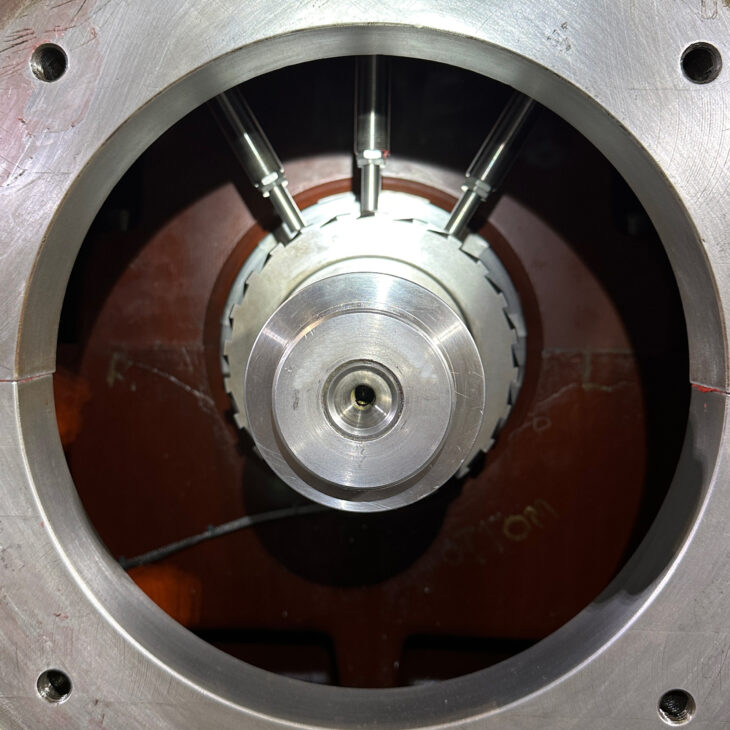

The overspeed protection upgrade was achieved with The Istec SpeedSys 300 (SIL3). Six SpeedSys 300 modules were pre-engineered and assembled into two 19” rack-inserts at the Istec workplace, streamlining the on-site installation process in the new cabinet to just a single day. The existing speed sensors were replaced with three DSF 1210 Hall-effect sensors.

To ensure the new system’s effectiveness and seamless integration, a comprehensive Site Acceptance Test (SAT) was performed at the plant during a scheduled turnaround. Following the successful SAT, the SpeedSys 300 system was officially commissioned, enhancing the plant’s operational safety and availability.

Deliverables

- Full scope supply and support of speed hardware and installation

- Installation of the Istec SpeedSys 300 system (6 modules) in rack-inserts for advanced SIL3 and protection.

- Dedicated overspeed protection system (SIL3) that ensures adherence to the latest standards.

- The new cabinet was carefully prepared by a third party, allowing our specialists to install the SpeedSys 300 rack-inserts and replace the sensors within a day.

- SIL by design instead of SIL by proven-in-use. Read why this is important here »

Impact

The implementation of the Istec SpeedSys 300 system has aligned the plant’s operations with the latest standards, including the API670, enhancing safety and availability. This upgrade also modernized its machine protection capabilities, and is expected to significantly reduce the risk of machine failure, minimize downtime, and enhance the plant’s operational efficiency. This project marks a significant step forward in OCI Nitrogen’s continued commitment to operational safety.