Proof-testing overspeed detection systems (ODS) and replacing Jaquet FT3000 ODS with Istec SpeedSys 300 at a gas compressor station in Germany

Thyssengas is one of the leading gas transmission system operators in Germany. At their plant in Elten they operate two gas turbines that drive two gas compressors to maintain the pressure of the gas network, one for low and one for high pressure applications.

The Jaquet FT3000 overspeed detection system (ODS) was used for overspeed protection on the gas turbines. In cooperation with the TÜV, Istec annually performs the proof-tests of the FT3000 systems to maintain the safety integrity and adhere to the safety standards.

Due to the recent obsolescence of the Jaquet FT3000 system, spare parts are no longer available. Thyssengas decided to replace the system with the Istec SpeedSys 300 (SIL 3).

ODS proof-testing service

Bringing a turbine in an actual overspeed situation is not an option due to safety reasons. Instead, overspeed situations are simulated to proof-test the ODS. Istec uses the IST-101 3-channel frequency generator to proof-test the full loop, including sensors, cabling and the overspeed system (terminal connection). The probe adapter functions as a 3-channel pole wheel, to make the sensor detect (simulated) gear teeth. When actuated on the terminal connections of the rack, the IST-101 simulates the sensor itself.

The amount of speed wheel teeth and the rotational speed are simulated by using the IST-101. As the device has three channels, all sensors of the 2oo3 configuration can be tested individually, but various combinations can also be simulated. This is crucial for a full proof-test. To facilitate a full-proof test, several steps are taken:

- The sensors are tested separately (e.g., first sensor A, then B, then C).

- The sensors are tested in pairs (e.g., AB, then AC, then BC), to simulate 2oo3 voting.

- A cable breach is simulated by disconnecting a sensor cable while simultaneously simulating an overspeed signal to another sensor.

Replacing the obsolete FT3000 ODS with the SpeedSys 300 ODS

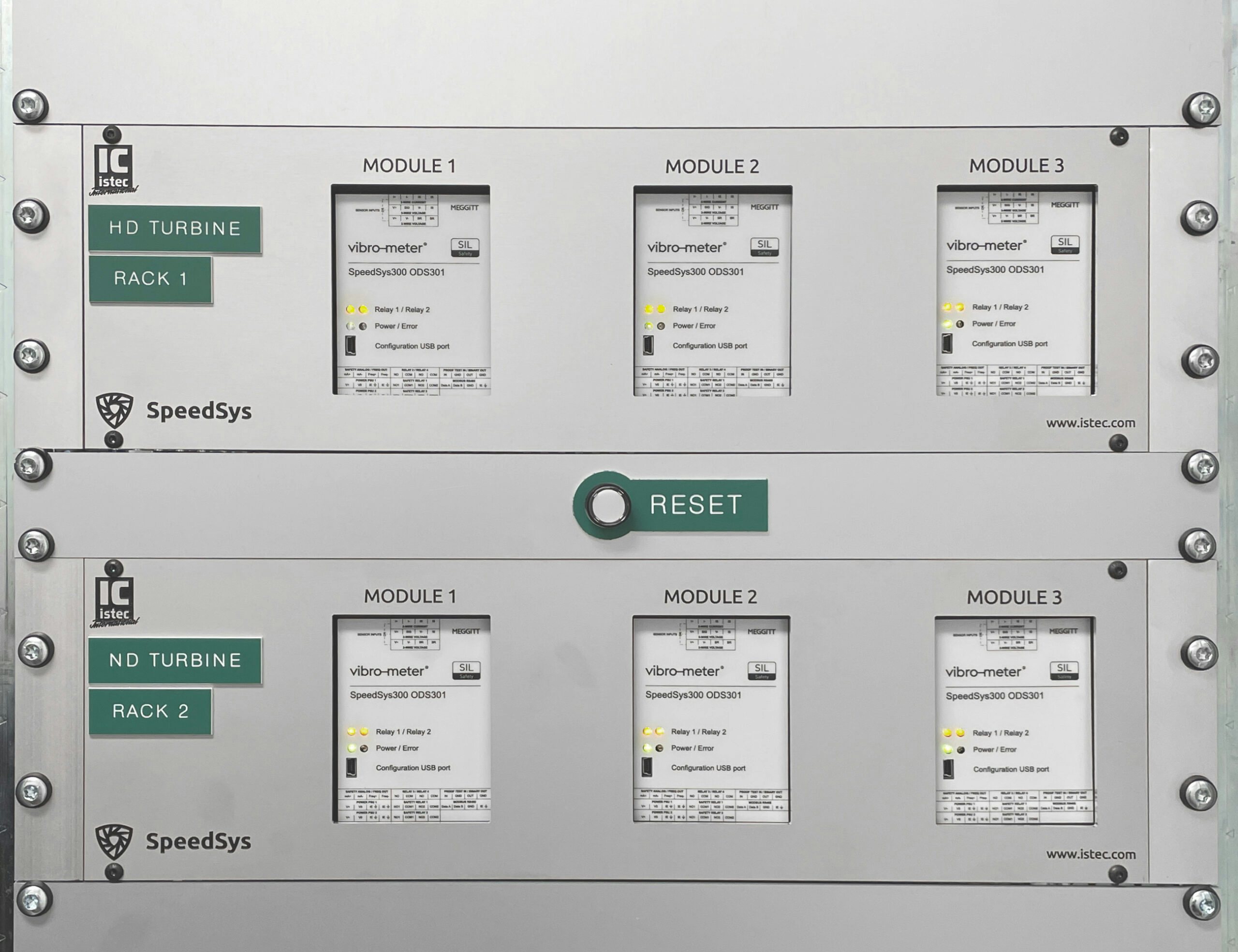

Thyssengas wanted to replace the current Jaquet FT3000 ODS with the SpeedSys 300 ODS, while maintaining the existing infrastructure. This meant that the SpeedSys 300 units, which are normally DIN-rail mounted, had to be installed in 19” racks in a 2oo3 configuration. The existing DSF 1210 Hall-effect speed probes were also kept in use.

Istec has pre-engineered the new SpeedSys 300 racks to be built into the existing cabinet, where the FT3000 rack was previously installed. The new installation includes a reset function to reset the SpeedSys 300 units after a trip has been initiated.

Learn more about the Istec SpeedSys 300 »

Learn more about the SpeedSys rack installation »

Deliverables

- 1-on-1 replacement solutions without the need for infrastructural adjustments

- Extensive full proof-testing of the overspeed detection systems, while negating the need for actual overspeed situations

- Full scope supply and support of speed hardware, installation and testing

- Fast troubleshooting, delivery, installation and commissioning

- SIL3 certified overspeed detection system with a proof-test interval of 10+ years

Impact

With the Istec SpeedSys 300 rack installations Thyssengas has a reliable overspeed detection system (SIL3) with a long proof-test interval. The replacement of the FT3000 rack with the SpeedSys 300 racks was successful, and benefits the reliability and availability of the gas turbines that drive the compressors.

The speed product brochure provides a complete overview of our tachometers, overspeed detection systems, and speed sensors.