Replacing an obsolete Jaquet FT3000 to a modern SpeedSys 200 overspeed detection system

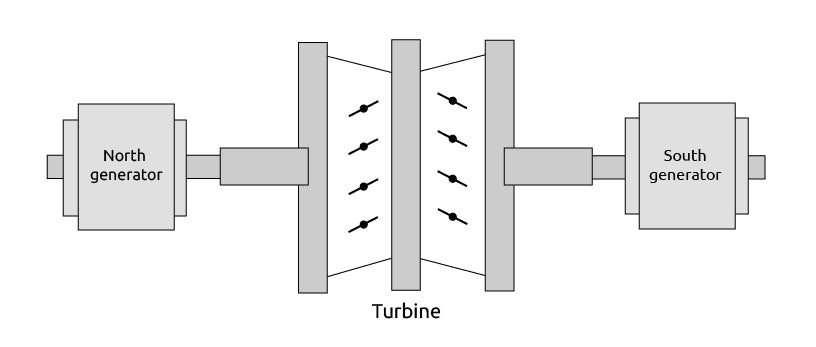

During the blast furnace process at Tata Steel, gases are released that contain a lot of energy. These gases are used to drive the gas expansion turbine (expander), which subsequently drives two generators. Using the energy stored in the excess gasses is a cost-effective way of reusing these gasses, which would otherwise serve no other purpose. Therefore, the expander and the two generators have an important function for the process.

Challenge

Tata Steel noticed an issue with one of the speed sensors, which is part of the overspeed protection system. Istec was asked to replace all of the speed sensors in the 2oo3 configuration with new Hall-effect speed sensors, followed by testing and verifying the overspeed detection system (ODS) and the new speed sensors.

During these tests the ODS showed abnormal behaviour and was not functioning like it should. It was not clear where the malfunctioning of the ODS originated from. This left Tata Steel with two options: to completely check the overspeed system, the internal wiring and its functionalities (1), or to replace the entire system with a new ODS (2).

As the FT3000 ODS is discontinued by its manufacturer (Jaquet) and spare parts are no longer available, Tata Steel decided to replace their current system and purchase and implement a modern ODS: the Istec SpeedSys 200.

As downtime is costly, a fast process was essential; delivery within a week, engineering within a day, and installation within a day. While this is quite challenging, Istec has the in-house capacity and capability to do so.

Tata Steel preferred a replacement solution that would keep the necessary infrastructural adjustments to a minimum, which required a bit of custom engineering by our specialists.

Solution

To facilitate the required engineering Istec mapped the existing hardware, including every sensor and all inputs and outputs, as well as all the (safety) functions of the existing ODS.

Old system

The obsolete FT3000 system was configured with the following 19” cards:

- Three FTFU3024 overspeed detection cards

- A FTW3013 analogue output card to PLC/DCS

- A FTK3072 communication module to a PC

The 24Vdc power supply was directly connected on the back of the rack. No filters or additional power supplies were used.

New system

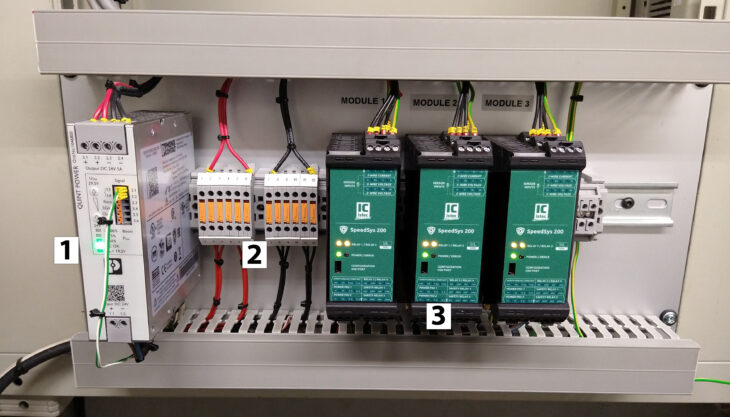

The FT3000 was replaced by a 2oo3 SpeedSys 200 installation. The DIN-rail assembly as shown in the image below was prepared on a 19” aluminium plate in our workshop, allowing for a quick and easy installation in the existing 19” rack, where the FT3000 system was previously installed. This installation covers all the core functions of the obsolete FT3000 that was replaced.

Deliverables

- Full scope supply and support of speed hardware and installation

- Custom engineering by Istec specialists

- The new installation covers all of the core functions of the previous installation

- Fast troubleshooting, delivery, installation and commissioning.

Impact

The new SpeedSys 200 installation fits the requirements of Tata Steel, featuring all the core functions of the previous ODS without the need for significant infrastructural adjustments. This low-impact installation is SIL 2 certified by design, as opposed to proven in use, making its required test interval much longer than the previous FT3000 installation. The gas expansion turbine can now safely operate without interference of a malfunctioning safety system.