In the production process of a dairy manufacturer, dust generation occurs. Air extraction systems remove the air with dust particles and direct it to a filter, where it is cleaned by industrial filtration systems.

As filter elements wear, the dust content in the exhaust air can increase, potentially resulting in non-compliance with environmental standards. Continuous dust measurement monitors this process so that action can be taken if the concentration becomes too high.

Solution

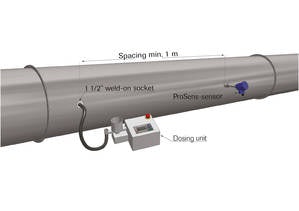

The ProSens can be calibrated to continuously monitor the cleaned air behind a filtration system for permissible dust concentrations.

Calibration

Using ENVEA’s Dosed-Reference Method, the ProSens can be calibrated quickly and safely at the customer’s facility. All that is required is a representative sample of the customer’s filter dust and some process parameters, such as volumetric flow rate. This information allows a specially developed dosing system to be pre-set, and the allowable dust concentration can then be specified. This calibration process is then used on-site at the customer’s location to set the sensor as a reference.

Customer Benefits

- Robust, durable, and reliable sensor (ProSens)

- Simple, quick, and verifiable calibration (Dosed-Reference Method)

- Guaranteed compliance with permitted thresholds (mg/m³)