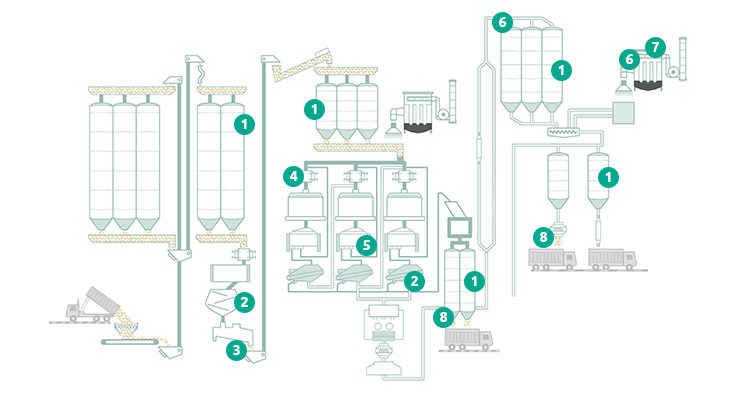

Grain is one of the most important arable crops in the Netherlands. Various processes are needed to convert raw grains into usable nutrients. In this article, we highlight the equipment we offer for flow and dust measurements in each subprocess to control and monitor this process.

- ProGap for level monitoring of storage silos

- Paddy for sieve break monitoring

- MaxxFlow for mass flow measurement of grain after the cleaning process

- FlowJam for Flow/NoFlow detection in flow direction to rollers

- M-Sens 3 for continuous moisture measurement before and after grain moistening

- Dusty or ProSens for monitoring filter leakage

- Airsafe for continuous monitoring of dust in ambient air

- MaxxFlow for loading trucks to prevent overloading

Monitoring of filter installations

After the grain is delivered, it is temporarily stored in silos. To prevent the silos from overloading, it is important to monitor the level. This can be done with ProGap sensors (1), which measure the level of the silos.

The first steps in the entire process are filtering, washing, and cleaning the raw material. Filtering is done with a shaking sieve, which removes stones and other unwanted particles from the raw material. It is important to monitor the sieve for holes and cracks because, if a hole or crack occurs, a large production batch may need to be discarded, as quality and safety can no longer be guaranteed. With the Paddy (2), it is possible to check whether oversized particles are present in the process after the filtration system. The Paddy can be used in virtually all types of industrial sieve installations and filtration systems, such as a tumbler sieve, vibrating sieve, drum sieve, and control sieve.

The first steps in the entire process are filtering, washing, and cleaning the raw material. Filtering is done with a shaking sieve, which removes stones and other unwanted particles from the raw material. It is important to monitor the sieve for holes and cracks because, if a hole or crack occurs, a large production batch may need to be discarded, as quality and safety can no longer be guaranteed. With the Paddy (2), it is possible to check whether oversized particles are present in the process after the filtration system. The Paddy can be used in virtually all types of industrial sieve installations and filtration systems, such as a tumbler sieve, vibrating sieve, drum sieve, and control sieve.

Once the raw material has been cleaned and filtered, a non-contact flow meter, such as the MaxxFlow (3), is used to measure the mass flow. This allows monitoring of how much raw material is being processed. The grain is then temporarily stored in silos before entering the processing stage. Again, level measurement and monitoring are carried out in these silos using ProGap sensors (1) to prevent overloading.

Roller mills and malting

To monitor the grain flow towards the roller mills, a FlowJam (4) is used for Flow/NoFlow detection. This allows blockages in the grain supply to be quickly detected. If there is a risk of bridging in the silo, it is possible to install a FlowJam under each silo. This helps to quickly identify which silo is experiencing supply issues.

To monitor the grain flow towards the roller mills, a FlowJam (4) is used for Flow/NoFlow detection. This allows blockages in the grain supply to be quickly detected. If there is a risk of bridging in the silo, it is possible to install a FlowJam under each silo. This helps to quickly identify which silo is experiencing supply issues.

For the best end result, a small amount of water is added to the grain before the grinding process, after which the moist grain is led to the roller mills. To know how much water needs to be added, the M-Sens (5) is used to monitor the moisture content. Additionally, an M-Sens (5) is placed for continuous moisture measurement after moistening to ensure quality.

After moistening and grinding the grain, everything is sieved again. With the Paddy (2), it is possible to check whether oversized particles are present after the filtration process. If this is the case, it may indicate a crack in the sieve. When oversized particles are detected, a signal is given, allowing an operator to intervene quickly and limit production losses.

Detection of dust leakage in dust collection filters

After the raw grain has been ground into coarse particles, it is directed towards silos. Despite the grain being moistened, dust can still be released during the grinding process. In the silos, this dust is captured by filters, and the ProSens (6) can create a trend of the filter performance. This allows the operator to predict when the filter needs to be emptied or replaced.

After the raw grain has been ground into coarse particles, it is directed towards silos. Despite the grain being moistened, dust can still be released during the grinding process. In the silos, this dust is captured by filters, and the ProSens (6) can create a trend of the filter performance. This allows the operator to predict when the filter needs to be emptied or replaced.

Air ducts / ventilation ducts

Throughout the process, there is a risk of dust formation. At various points within the process, dust extraction takes place, with the air ventilation ducts passing through a filter housing. To monitor whether the filter bags (also called bag filters or sleeve filters) are filling up, a trend of the filter performance needs to be created. This trend can be formed using a Dusty (6) or a ProSens (6).

In filter housings, it is important to monitor the ambient air inside the filter housing using the AirSafe (7). The AirSafe from Envea offers an effective solution for monitoring and controlling dust concentrations in a room. This solution helps prevent dust explosions, safely monitor dust concentrations in work environments, and quickly detect dust escaping from a system (for example, due to a torn filter).

Loading trucks

The end product can be sent to customers in various forms. This is done in bulk packaging, but for large volumes, for example, by tank transport. To measure how much material is being loaded into a truck, the MaxxFlow (8) can be used. This mass flow meter is specially designed for non-contact mass flow measurement. In addition to understanding how much raw material is being loaded into the truck, overloading can also be prevented.

The end product can be sent to customers in various forms. This is done in bulk packaging, but for large volumes, for example, by tank transport. To measure how much material is being loaded into a truck, the MaxxFlow (8) can be used. This mass flow meter is specially designed for non-contact mass flow measurement. In addition to understanding how much raw material is being loaded into the truck, overloading can also be prevented.