Oil-tight RTD bearing sensor – Istec RTD580

The RTD580 is an oil-tight RTD bearing sensor that measures bearing temperatures on industrial rotating equipment; a key indicator for oil film and bearing health monitoring. Its small sensor tip allows for quick measurements and easy installation, while different cabling options offer excellent durability in harsh environments.

Unique oil barrier

The sensor comes with a unique oil seal which is designed to withstand temperature fluctuations and prevent any oil pass-through over time.

Negates the need for oil drainage

Due to its oil-tight design oil drainages due to leakages are no longer required, nor the necessity to regularly empty these.

Leak-proof pressure tested

To ensure its leak-proof design and the quality of the manufacturing process, each oil barrier is thoroughly pressure tested (2 bar, 20 °C).

“The first fully oil-tight temperature sensor for rotating equipment“

Design & configurations

The transition piece has multiple oil barriers to ensure that the sensor is leak proof. Combining the sensor with the optional sealing gland makes the sensor fully oil-tight.

Different sensor configurations are available, including different cable materials and sizes. Refer to the datasheet in the download section below for details.

The RTD580 sensor offers an affordable oil-tight solution for slide bearing / plain bearing applications, both for OEMs and end-users. Applications include turbines and compressors in energy, oil & gas, chemical, and petrochemical industries.

Suitable for harsh environments

The sensor is designed to be used in harsh environments, with excellent durability. It can be used for applications up to 5 bar.

Miniature bearing sensor

The RTD580 has a small sized sensor tip for easy installation and quick temperature measurements. Its suitable for any slide bearing application.

Advanced cabling

Its cabling is designed to be resistant to thermal stress and mechanical deformation. Its design also prevents capillary action inside the cabling.

Multi-sensor sealing gland

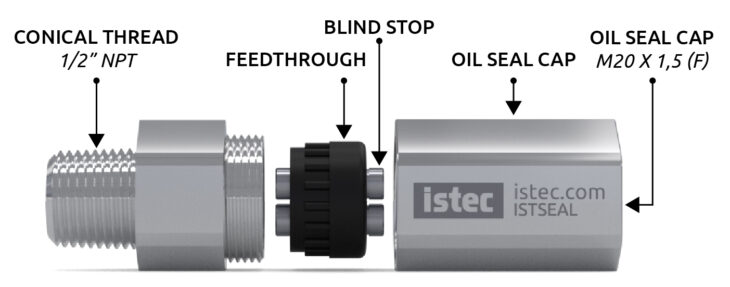

The multi-sensor sealing gland is designed to create a safe and reliable pass through for up to four temperature or proximity sensors on industrial machinery. The sealing gland is easy to install, and its design enables users to use one gland type all over the machine which contributes to the machine’s manageability and to reduce number of spare parts.

1/2″ NPT conical thread

The conical stainless-steel thread is easy to install.

Viton compression seal

The viton seal has four feedthroughs to place up to four sensors. Viton is resitant to oils, aqueous media, and most other fluids. Unused holes can be closed with the blind stops.

Oil seal cap

The oil seal cap has a M20 x 1,5 Female conduit adapter connection.

Downloads

Datasheets

Whitepaper

Ask our expert

Buy at the Istec webshop

Istec RTD580 bearing temperature sensor

Order this sensor directly via our shop!Istec oil-tight bearing temperature sensors

Do you prefer a PDF version of this whitepaper? Click here » A completely oil-tight bearing temperature sensor range to prevent oil-leakage Temperature sensors are used in many industrial applications…

Temperature measurements for reciprocating compressors

This article is part of the whitepaper: “monitoring mechanical behaviour of reciprocating machinery”. Request the whitepaper here » Temperature monitoring is essential for various components of reciprocating compressors. This article…

Case: custom temperature sensor that is resistant to vibrations

How do vibrations affect temperature measurements? Before we describe the case, we will first explain the effect vibrations can have on temperature measurements. Whether the vibrations are constant or sometimes…