Monitoring rider band wear on a 4-cylinder reciprocating compressor

Reciprocating compressors are critical assets in a wide range of industries such as (petro)chemical, power and oil and gas. Reciprocating compressors are, compared to comparable machinery, very maintenance-demanding.

During its reciprocating motion the piston moves through the compressor cylinder, supported by rider bands. The rider bands make sure there is no metal-to-metal contact between the piston and the cylinder wall. Due to large mechanical forces in their construction and high stress factors, these rider bands wear out in time. Depending on the application this may take weeks or months, but is in any case inevitable.

Monitoring this key mechanical indicator allows for the efficient scheduling of replacing the rider bands. Yet, many companies do not have the means to accurately monitor rider band wear, but rely on periodic manual inspections to assess and replace the rider bands.

RecipSys 200 – Monitoring rider band wear

The RecipSys 200 is a compact monitoring system for reciprocating compressors. It delivers accurate real-time data of rider band wear, eliminating the need for periodic production shutdowns for manual inspections. The system offers scalability to fit each compressor configuration. Its modular design enables the user to integrate the system with any monitoring suite.

Read our case study for a practical example of the RecipSys 200 »

How to measure

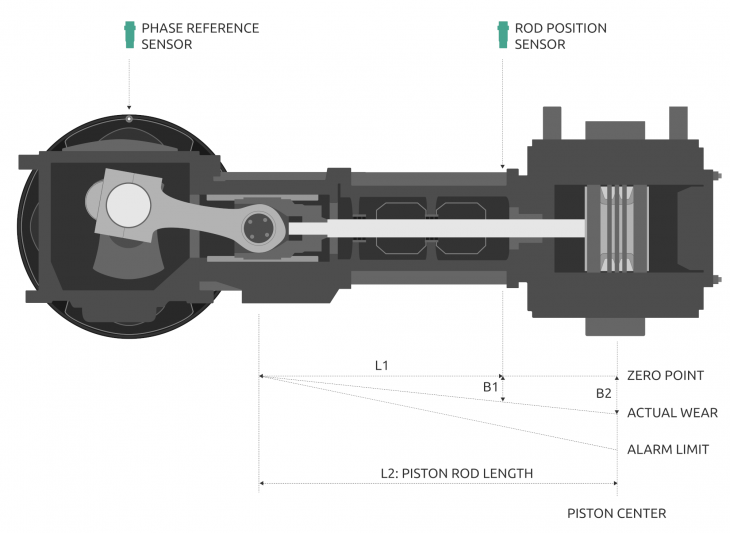

As measuring the rider band wear directly is difficult, due to the high pressure in the cylinder chamber, the vertical displacement of the piston rod is measured instead. As the rider bands wear down the piston rod drops subsequently until it reaches a point that triggers an alarm (Figure 1).

Phase trigger

The RecipSys 200 uses a phase trigger (reference) to determine the right phase angle for the rod drop measurement, making it much more accurate than any overall measurement.

Rod position sensor

A proximity probe is placed perpendicular to the piston rod. It measures the vertical displacement of the piston rod, which is a direct effect of rider band wear.

Monitoring rider band wear on a 4-cylinder reciprocating compressor

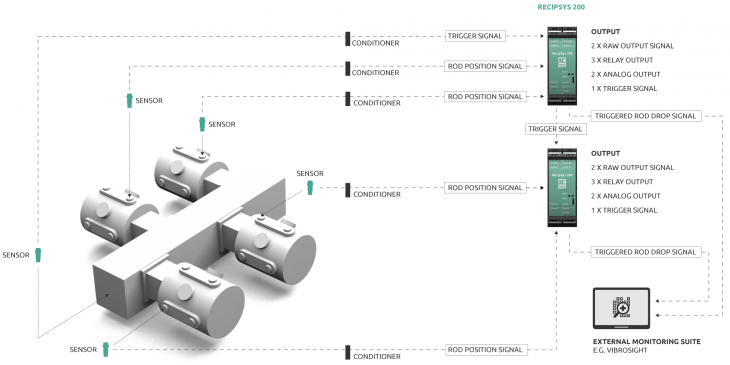

To monitor rider band wear on a 4-cylinder application four rod displacement inputs are required. The RecipSys 200 has two rod displacement inputs, making two units sufficient for this application. While each unit has its own phase trigger input, only one is used when connecting 2 or more units.

The system has two raw outputs that can be used for external signal analysis, or as output for analysis with existing monitoring suites (e.g. vibration or temperature).

The three relay outputs can be used to trigger alarms for rod drop, peak-to-peak and/or sensor and system OK functions.

The two analogue outputs (4-20 mA) can be used for local display and/or DCS. If the RecipSys 200 is connected to another monitoring system with a dynamic input the rod position signal can be used for trending with the corresponding monitoring suite (e.g. Vibrosight).

The RecipSys 200 has one trigger signal output which is used to link multiple units for applications with 3 or more cylinders. Only one phase trigger sensor is needed, regardless of the compressors’ configuration.

Other applications

Due to its scalability the RecipSys 200 can be used for any reciprocating compressor configuration, including 1-, 2-, 4- and 6-cylinder compressors. Multiple units are easily connected for larger applications. The system can be integrated with existing monitoring systems and analysis software, ensuring a low technical footprint.