Excessive vibrations on rotating equipment like pumps, gearboxes, turbines and compressors are a clear sign that the equipment is not functioning properly. Equipment that is showing excessive vibrations will most likely not achieve the expected lifespan, and can be the source of unscheduled downtime or dangerous situations. Therefore, it is important to find the root cause of vibrations by measuring and analysing the vibration signals. Common causes of vibrations are discussed below.

Alignment problems

When two or more rotating machines are connected, the correct alignment is crucial.

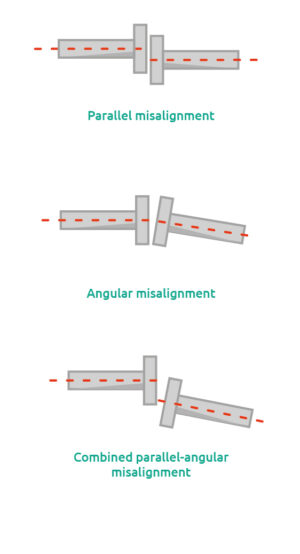

Typical alignment errors are:

- Parallel misalignment:

The shaft centre lines are parallel but are not in line. This can be both horizontal and vertical. Parallel misalignment is also known as offset misalignment. - Angular misalignment:

The shafts meet at a point, but are not parallel. This can be both on the horizontal and vertical axis. Angular misalignment is also known as gap misalignment. - Combined parallel-angular misalignment:

A combination of both parallel and angular misalignment. Combined parallel-angular misalignment is the most common misalignment.

Unbalance

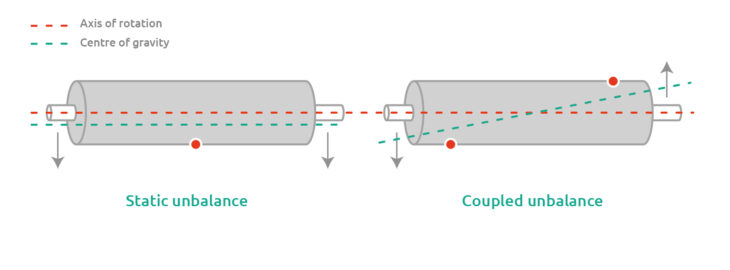

When the centre of gravity of a rotating object is not exactly in the centre line, it causes machine unbalance resulting in vibration. When a machine is unbalanced, it can cause damage to the machine itself, the foundation, pipes, etc. There are three types of unbalance: static unbalance, coupled unbalance and dynamic unbalance.

Static unbalance

Static unbalance is when the centre of gravity axis (inertia axis) is not in line with the centre of rotation (shaft centre line), and the heavy spot and the centre of gravity are in the same plane. Static unbalance can be the result of a parallel displacement of the principal mass axis relative to the shaft centre line, and can be caused by non-symmetric mass distribution or deformation. In theory, static unbalance can be detected by placing the object with a point of rotation on each end. When there is static unbalance and friction is zero, gravity will turn the heavy side downwards.

Coupled unbalance

Coupled unbalance appears when a rotating object has two or more unbalanced masses in different planes, that equal each other out in rest position. The principal mass axis is no longer in parallel to the centre of gravity, but crosses the centre of gravity axis. When the system starts to rotate, these masses will be influenced by centrifugal forces, resulting in vibration.

Dynamic unbalance

Dynamic unbalance is the most common type of unbalance and the result of static and coupled unbalance. The principal mass axis is displaced and not parallel to the shaft centre line.

Resonance

Every machine has one or more resonance frequencies (natural frequency). When a rotation frequency coincides with the resonance frequency of the machine, resonance occurs. Resonance can have major impact.

Loose parts

Loose bearings, loose bolts and corrosion can cause the machine to vibrate excessively. Due to the mechanical forces in the machine, loose parts can rapidly cause damage.

Dynamic unbalance is the most common type of unbalance and the result of static and coupled unbalance. The principal mass axis is displaced and not parallel to the shaft centre line.

Bearing damage

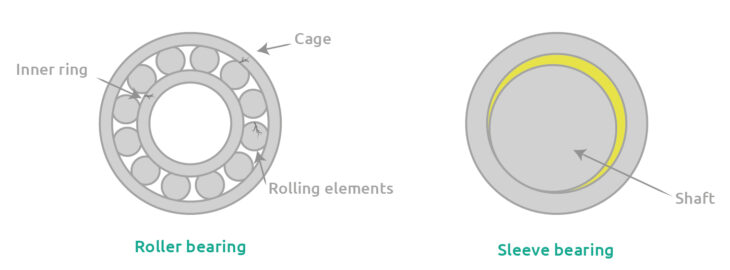

In rotating machinery, we come across two main types of bearings: roller bearings and sleeve bearings.

A roller bearing can be damaged in several ways, each with its own vibration fingerprint:

- Damage to the inner ring

- Damage to the outer ring

- Damage to the cage

- Damage to rolling elements (e.g. cylinders, cones and needles)

Each part of a roller bearing has its own frequency. By calculating these frequencies, it is possible to use vibration analysis to determine whether the vibrations are a result of bearing damage.

In contrast to roller bearings, sleeve bearings do not use a rolling element, but use a fluid (oil) film to reduce friction. Vibrations can be caused by inaccuracies in the fluid film; if a stable oil film cannot be formed, it can break, resulting in an oil whip or oil whirl. Additionally, this type of bearing is more sensitive to external influences on the position of the shaft, because its position in the bearing is not fixed.

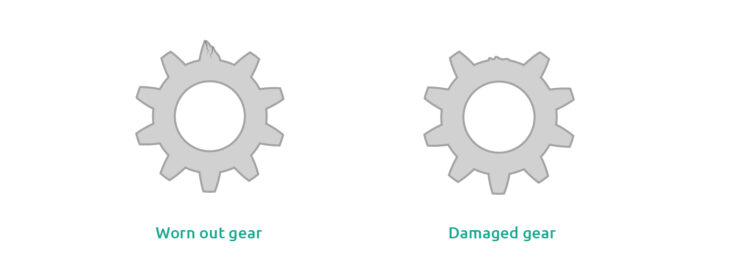

Damaged or worn out gears

Gearbox vibrations are often caused by damaged or worn out gear teeth. When gear tooth engagement involves a damaged tooth, the force cannot be transferred as with the other gear tooth engagements. If a gear tooth is broken, less force can be transferred at this point of the cycle. Vibrations occur as a result.